FILTER MONITORING SYSTEMS

The Filter Monitoring System by RTT is used to monitor the condition of the exhaust filters and notifies the status of the filtration to operators, paint line managers, or management teams.

Notifications range from visual indicators on the panel face to emails and text messages depending on the version of monitoring required.

The ability to understand the condition of the exhaust filter load dramatically affects the efficiencies of spray booth operational cost due to unnecessary filter change-outs.

This system is a stand-alone unit that can be added to any existing or new spray booth and powered by a regular 120 volt outlet by using the provided power cable.

Retrofitting capabilities are not just limited to RTT Engineered Solutions equipment but also other manufactures of spray booths.

It is recommended each exhaust chamber is monitored on a spray booth.

FILTER Monitor Pro

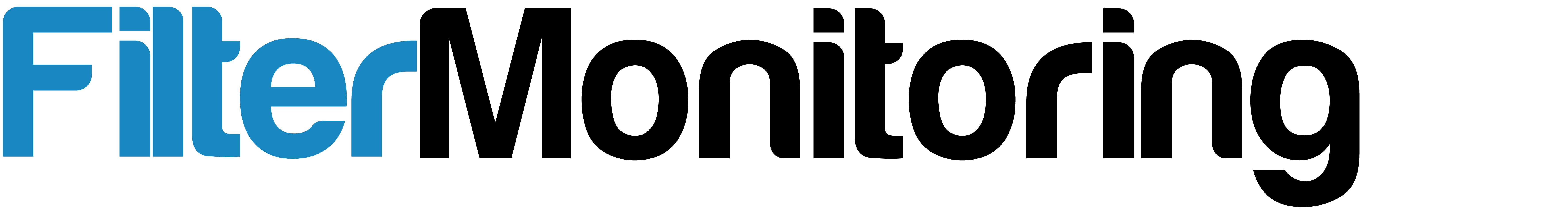

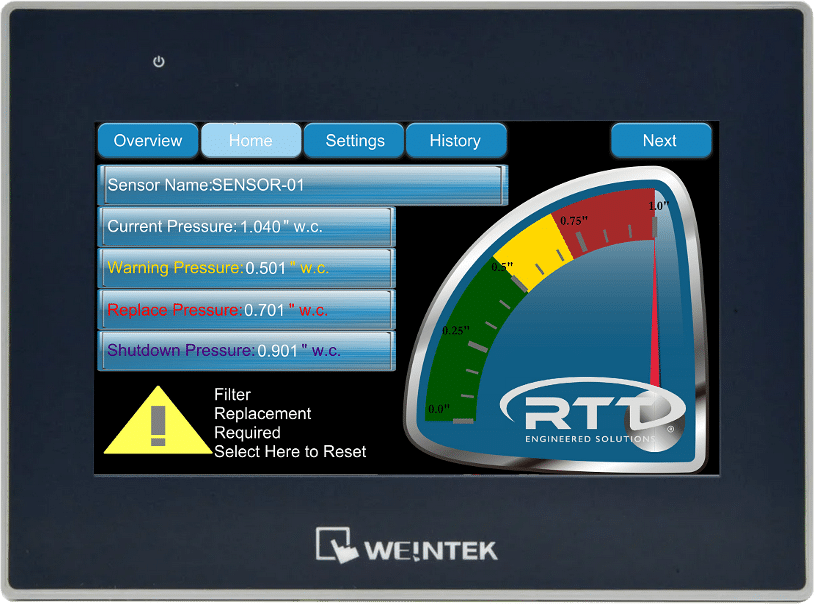

The RTT Engineered Solutions Filter Monitor Pro is designed to give operators and managers visual indication when filter maintenance is required. It includes 3 user adjustable set points for each sensor (filter stage) being monitored.

The pressure readings are gathered by external pressure transmitters (sensors) that are installed near the filters. The pressure transmitters measure the pressure across the filters using poly tubing connected to pressure ports mounted in the wall of the filter chamber. When the fan is turned on, a pressure differential is created from the front side of the filter to the back side of the filter. As the filter loads with overspray, the pressure differential increases. The transmitter converts the pressure differential into an electrical signal that is sent back to the Filter Monitor Pro which is then converted into a numerical value and displayed on the touch screen.

User Adjustable Set Points

The Filter Monitor Pro allows for 3 pressure set points to be entered into the settings menu.

- Warning Pressure: Turns the stack light yellow and alerts the operator that the filters will need to be replaced soon.

- Replace Pressure: Turns the stack light red and alerts the operator that the filters require replacement.

- Shutdown Pressure: Disables the dry contact interlock that can be used to turn off other equipment in the system such as spray equipment, compressed air solenoids, or conveyors.

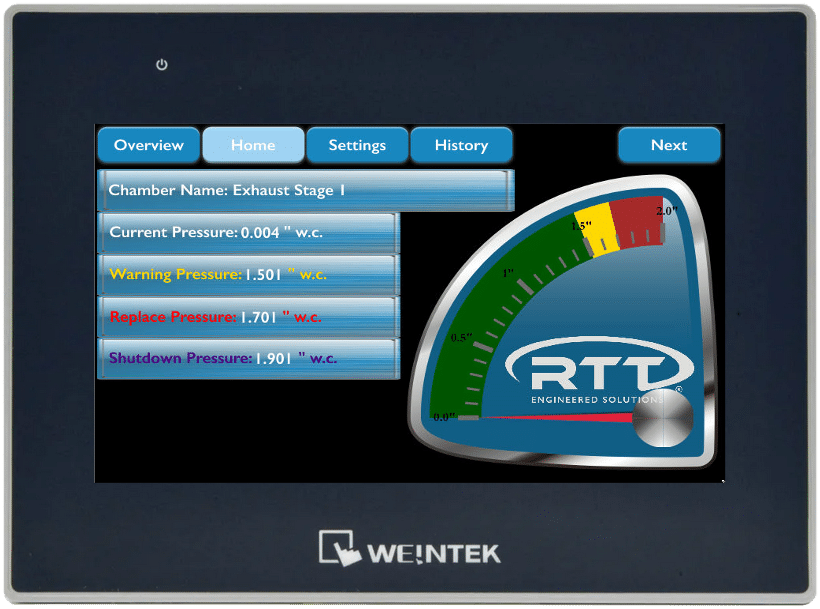

Data Acquisition & Recording

Pressure readings are stored in the touch screen memory to allow managers to review how long the filters lasted before needing to be replaced. This allows for scheduled maintenance for filter change outs and estimating filter expenses and quantities throughout the year based on previous usage history. This data can help purchasing managers ensure the correct amount of filters are on hand when needed.

Electronic Notifications

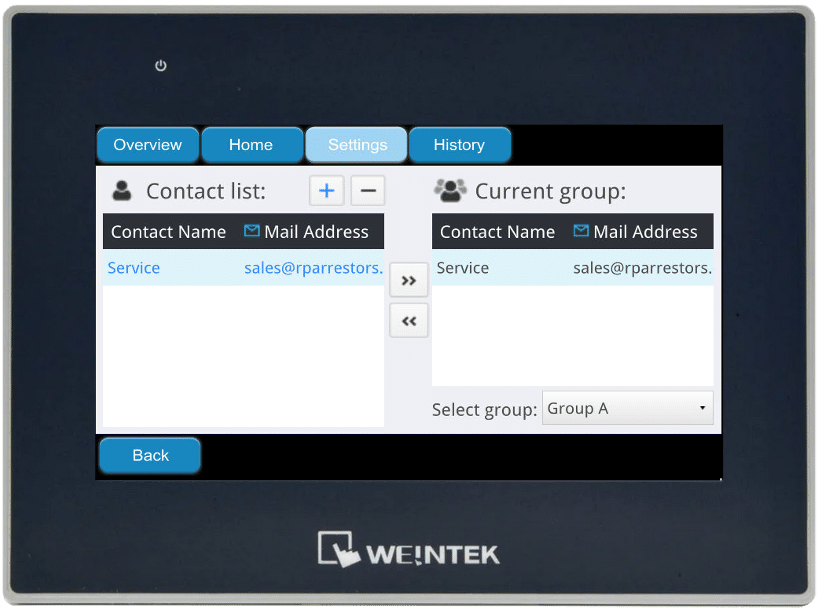

When the Filter Monitor Pro is connected to an active internet connection via ethernet, notification email and text messages can be sent to anyone that has been entered into the contacts list.

What’s Included

- 7” Color Touch Screen

- Omron CP Series PLC

- Analog Pressure Transmitters with tubing & fittings (1 per filter stage)

- RGB LED Stack Light

- Side mounted IEC power inlet & CAT6 RJ45 port

- Front mounted USB port

- Type12 NEMA Enclosure (UL Type1)

- UL 508A Listing

Ordering Information

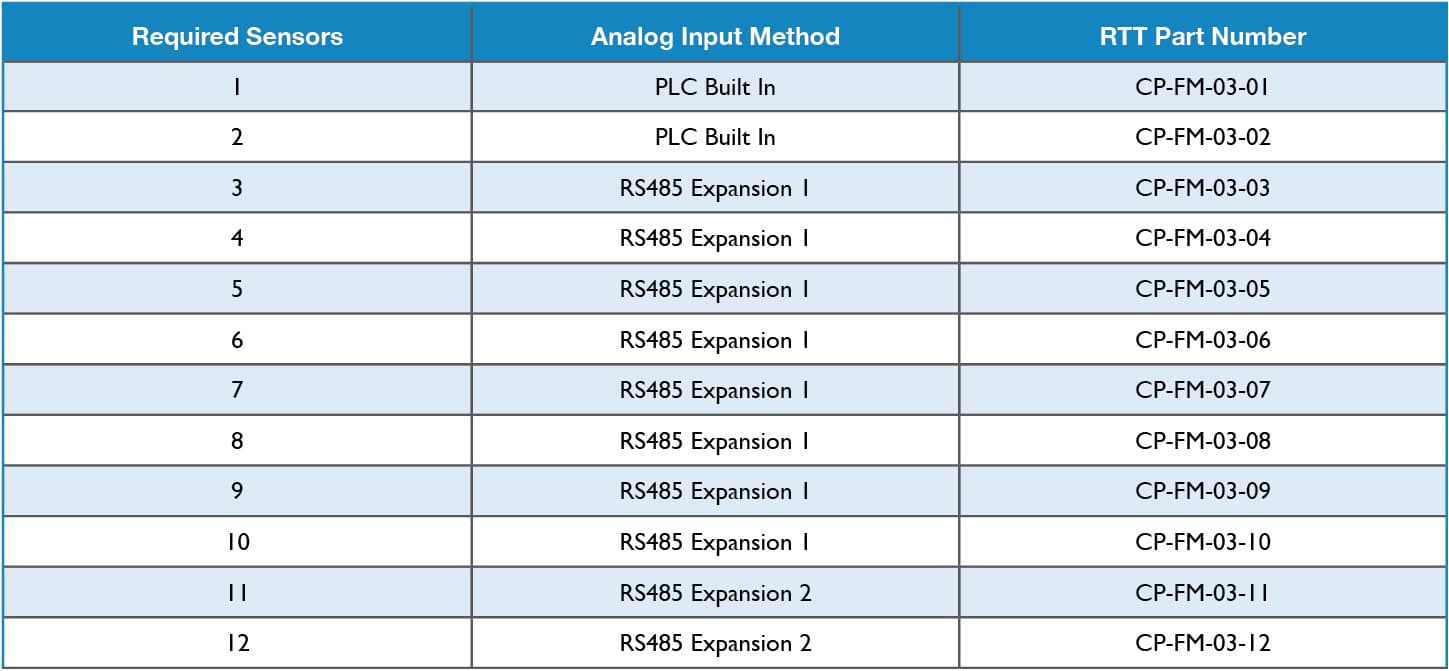

The RTT Engineered Solutions Filter Monitor Pro can monitor up to 12 sensors. Each sensor would be placed across a stage of filtration. If 3 stage filtration is used, 3 sensors would be required. If a booth has 4 chambers of 3 stage filtration, 12 sensors would be required.

Optional M12 Cable Assemblies

Simplify installation of your Filter Monitor Pro by purchasing the M12 field wiring kits. Using M12, up to three sensors can be combined into a single cable. The cables provide for a secure plug & play wiring method using threaded connectors. M12 cables can be joined together to provide additional length where required. Cable lengths available are 1-meter, 5-meter and 10-meter. Sensors will arrive pre-wired with a 1-meter pigtail.

FILTER Inventory Management

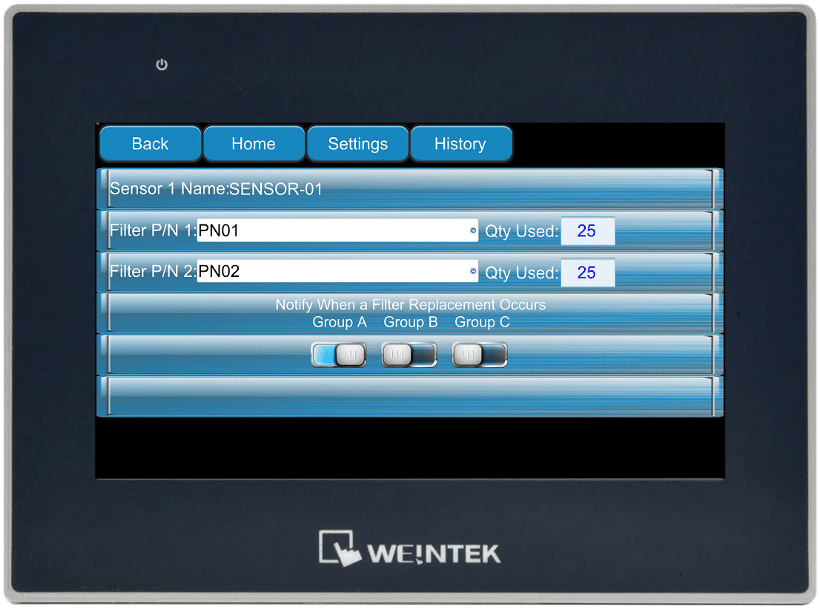

With the inventory management system, the operator can enter up to two filter part numbers per sensor along with in-stock quantity, quantity used per change out, and minimum in stock quantity. When replacement filters are received, the operator can add the replacement amount to the in-stock quantity of each part number.

Multiple Part NumberS Per Sensor

During the initial setup, the operator can assign up to two part numbers to a specific sensor. The operator also enters the required quantity per change out and selects which email group to notify when the filters are replaced.

Replacement Required Notification

After a sensor exceeds the Replace Pressure Setpoint, a notification will appear at the lower left side of the screen alerting the operator to reset the filter chamber after the filters have been replaced.

Filter Resistance Airflow Control System

The Filter Resistance Airflow Controls System

(FRACS) by RTT is designed to maintain a constant airflow volume for your spray booth exhaust system when the ability to pressurize the booth enclosure is not possible.

This upgrade to the normal RTT control package will autocratically adjust the exhaust fan speed as the exhaust filtration loads.

- Initial FPM set point is setup by using handheld velometer and adjusting panel mounted potentiometer to achieve desired FPM with clean filters.

- Set point potentiometer is mounted inside control cabinet to reduce tampering.

- Transmitter uses 0-10vdc signal to VFD for simple troubleshooting.

- The FRACS can be retrofitted to any existing spray booth with little to no additional components.