SMARTBATCH PART TEMPERATURE

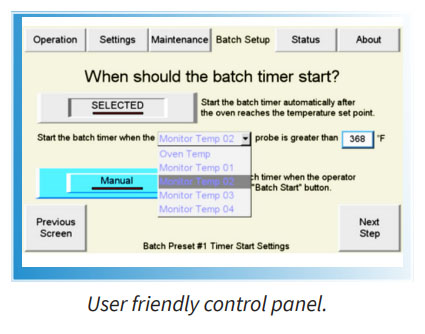

RTT’s new patent pending SmartBatch technology allows for “real-time” monitoring of part temperature. SmartBatch technology incorporates part temperature probes into the design of the batch oven and control panel for monitoring part temperature during the cure process. The information can then be used to control cure time cycle as well as document the part curing process. The SmartBatch technology allows better control of the cure process, cure temperature and energy consumption thus providing energy savings. When used in conjunction with the RTT SmartConnect App, you can remotely monitor part and oven temperature, batch time, system faults or out of range occurrences with any Android, PC or Apple device.

FEATURES & BENEFITS

- Reduced energy consumption by starting batch timer after part reaches desired temperature set point.

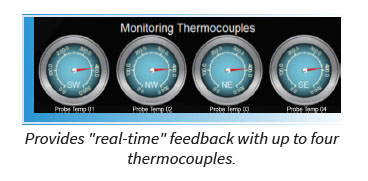

- Ability to view “real-time” part temperature of each independent probe for oven time and temperature minimizing energy and saving money.

- Reduces rework for parts not reaching cure temperature by monitoring part temperature.

- Temperature recordings can be exported from touch screen via email or USB.

- Monitor and record up to four sensors at a time.

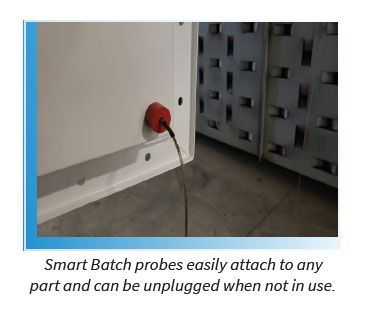

- Part sensors can be unplugged if monitoring is not required.

- Air and part temperature data can be stored for future reference allowing accurate record keeping of individual batches.

- SmartBatch eliminates the need for additional expensive part temperature measuring devices (ie; datapaq).

- Magnet or clamp sensors available