Insulated Oven Panels

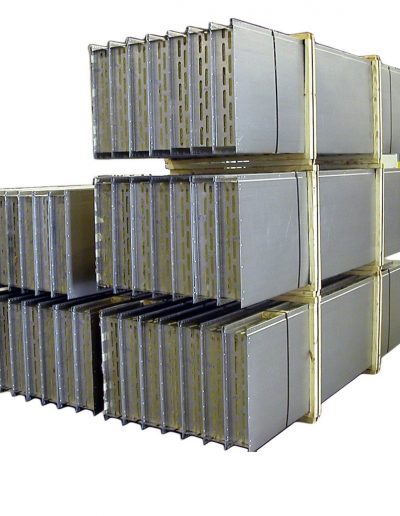

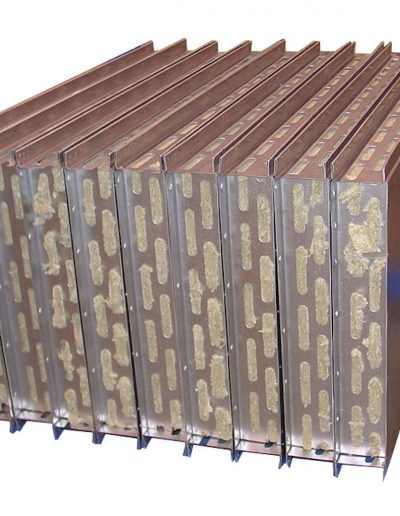

RTT’s high-quality insulated panels are used in a wide range of applications including dry-off and curing ovens, as well as environmentally controlled rooms. Insulated panels are constructed of 20-gauge prime aluminized steel and available in a wide range of thicknesses including 2”, 3”, 4”, 6” and 8” based on application and insulating properties required.

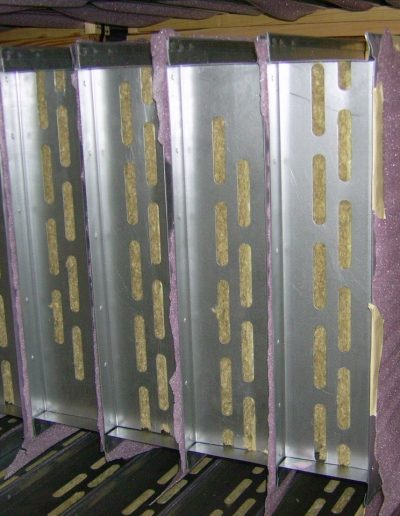

RTT insulated panels are rigidly constructed utilizing “knuckle” punch for attachment of the top and bottom connecting panels and a “button” punch along the tongue and groove surfaces. This assembly process provides superior strength while protecting the cosmetic appearance of the panels.

Panels are shipped in a vertical orientation to facilitate the installation of insulation into the channel prior to interlocking the panels during the construction phase.

Features

- Tongue and groove construction

- Variety of thicknesses available including 2″, 3″, 4″, 6″ and 8″

- Stiffener panels comprising the top, bottom and sidewalls of the panels

are factory punched to reduce the through metal, thereby reducing heat

transmission to the exterior surface of the panels - Where possible, standard 28 ½” panels are used, providing a net width of

27″. Panels can be made in a variety of widths up to 36″ - Available in lengths up to 15′, as well as custom lengths, upon request

- Standard 4 lb density semi-rigid/resilient insulation is provided, optional

density’s including 6 and 8lb can be provided - Powder coated white finish is an available option when used for

environmental rooms