PASS THROUGH POWDER COATING BOOTH

RTT offers a Pass Through Powder Coating Booth ideally suited for conveyorized coating applications looking for the most efficient system option. Our Pass Through Powder Booths are precision engineered to provide access for coating both sides using manual spray equipment, automatic spray equipment, or both. The conveyor slot in the top of the booth allows the racked parts to pass through the spray area with the conveyor installed above the booth. Overspray is minimized and productivity is enhanced while parts are handled in the most efficient manner possible. The booth also features a collector module that can be rolled away for easy color change and has additional modules available for multiple color operations.

Booth Features

- RTT booths are constructed from heavy duty 18-gauge, prime quality galvanized steel and engineered with corresponding support structure.

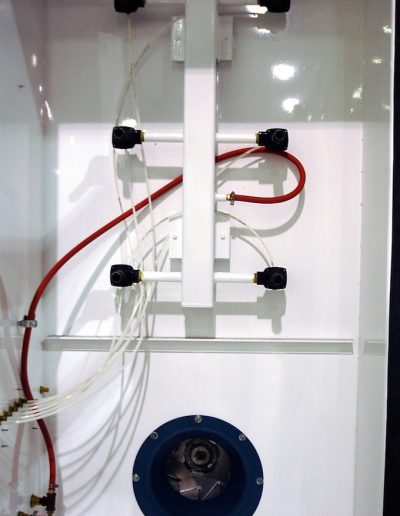

- Collector Module recirculates clean, filtered air into the booth and includes high quality primary filter and final filter modules. Factory-assembled, powder coated white mild steel construction with removable powder drawer.

- LED lighting is constructed of 22-gauge steel which is powder coated white, and available in 4000 and 8000 lumen models. E-Lights are ETL listed for US and Canada with Class 1 Division 2, Group A, B, C, D and Class 2 division 2, Group F and G ratings.

- Control Equipment Includes NEMA 12 UL and ETL listed control panel mounted to the side of the collector module, factory wired and tested. Automatic or manual cartridge filter pulse down mode; Door mounted magnehelic gauge for cartridge filter monitoring; VFD to control fan speed; Pressure switches to monitor final filter pressure and warn/ shutdown if pressure exceeds set point.

- Variable Frequency Controlled Fan (VFD) is connected to the fan motor, allowing the fan to turn at any speed so that optimum airflow within the booth can be achieved. The VFD can also save on operating costs due to the reduced amp load on the motor and the ability to slowly ramp the motor up to speed.

- Purge Control Assures the safe operation of the coatings’ enclosure, by maintaining airflow at design levels.

- RTT booths meet and/or exceed quality performance standards and all applicable OSHA and NFPA regulations.

| Interior Dimensions | Part Opening | Operator Access | Total CFM | |||||

| Model Number | Width | Height | Length | Width | Height | Auto | Manual | |

| EPB-05-08-14-PT-S | 5′-0″ | 8′-0″ | 14′-0″ | 3′-0″ | 6′-0″ | 2 | 2 | 7,000 @ 4.5″ SP |

| EPB-06-08-14-PT-S | 6′-0″ | 8′-0″ | 14′-0″ | 4′-0″ | 6′-0″ | 2 | 2 | 8,000 @ 4.5″ SP |

| EPB-07-08-14-PT-S | 7′-0″ | 8′-0″ | 14′-0″ | 5′-0″ | 6′-0″ | 2 | 2 | 9,000 @ 4.5″ SP |

PASS THROUGH POWDER BOOTH AIRFLOW

TParts enter the booth through conveyor openings, then pass the coating operator stations to receive the coating. The powder overspray is entrained within the air stream moving to the collector module, where the cartridge filters will remove the particulate. The containment air is drawn through the air handler’s primary and final filter system before being discharged back into the room. Coated parts exit the booth for conveyance to the cure oven.

PASS THROUGH POWDER BOOTH LIGHTING

RTT lighting is calculated and engineered using photometric software. Standard and custom lighting levels are easily accomplished with our E-light technology of LED fixtures.

E-Light fixtures are ETL listed and designed for proper use in spray booths. Because of this, our E-Light does not require a safety interlock saving on installation cost and additional maintenance. click here for more on RTT’s E-Light technology.

PASS THROUGH POWDER BOOTH CONTROLS

ETL-Listed With purchase of optional control panel. RTT provides a number of controls for your paint booth such as motor starters, multi-van, VFD controls and touch screen and PLC based controls. For more information on control options, please click here.

CARTRIDGE BATCH POWDER BOOTH OPTIONS

- For automatic guns, flame/spark detection can be provided by others (if required)

- Stainless steel option available

- Durable powder coated white option available

- Additional collection modules

- Touch screen controls

Code Compliance

RTT’s products meet and/or exceed all applicable OSHA and NFPA regulations.