Large Equipment Spray Booths- Success Story with DY Concrete Pumps

Selecting a Large Equipment Spray Booth manufacturer can prove to be a challenging task for many companies, but those that choose RTT Engineered Solutions as their spray booth provider will be pleased to experience a service that is second to none. From the initial design stages to final installation, the product you can expect to receive from RTT Engineered Solutions will be first class.

There are multiple variables that must be considered when choosing the size, airflow design, and construction of a Large Equipment Spray Booth. It is critical that these variables be dealt with properly to ensure the booth meets and exceeds the end user’s needs.

Chris Smith, DY Concrete Pumps General Manager, states, “Our efficiency has increased and as a result, we’re hunting outside work for the booth… I would love to get to a point where we are running the booth 24/7”.

DY Korea is currently the second largest hydraulic cylinder manufacture in the world. After more than twenty years supplying these products, DY expanded their product offering to include concrete pumps and in 2015 generated an international presence in North America. By combining the experience of DY Korea and DY North America, they supply the North American marketplace with hard-working, reliable concrete pumps that deliver performance at a competitive price.

The unique design of these concrete pump trucks requires a spray booth to have the ability to house both the vehicle and the extended boom in one space. With this expectation in mind, DY Concrete Pumps began the search for a spray booth that could increase their output and efficiency by coating the entire unit at one time.

For the last two years, DY has operated with a smaller booth that lacked the capability to coat an entire unit. “We had to do something, because we were starting to paint complete units and the size of the existing booth didn’t suffice. Our trucks are anywhere from 21 to 63 meters in length. We would have to paint part of the machine, take it out, fold it up, unfold it, and put it back in. Our efficiencies just weren’t great”, Chris explains.

DY Concrete Pumps knew their end goal was to find a company who could deliver a product to solve the problem at hand. Working with RTT Engineered Solutions as well as RTT distribution partners, DY began the consulting process to acquire a product that could meet the efficiency standards they were after while also increasing output and sales.

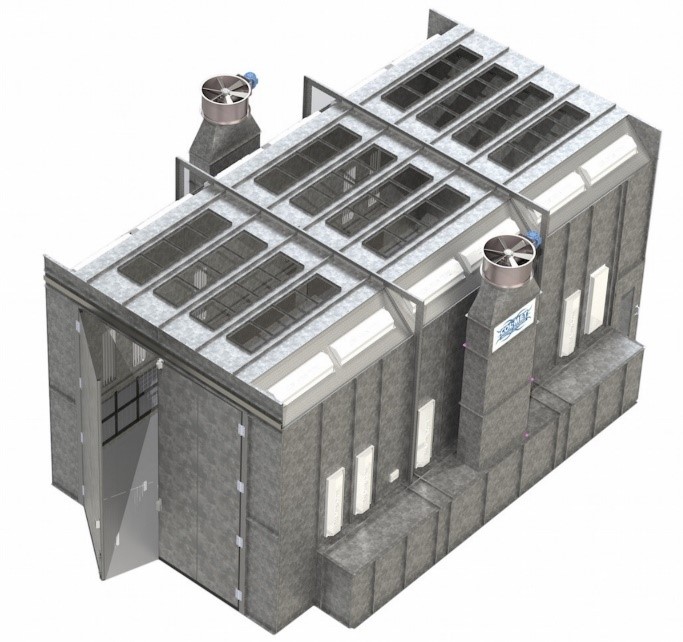

Once the size of the booth was determined, the design focused on the type of airflow required for a spray booth such as this one. Taking the size of the booth and the understanding that multiple painters would be working in the booth at the same time into consideration, a downdraft booth was determined the best airflow design.

“A lot of people hear “downdraft” and automatically think of pit downdraft; the mindset is that it always produces the best airflow”, says Trey Peavy, Director of Sales and Marketing for RTT. He continues, “of course, they work great, and it works with a project like this, as you have a larger product for the airflow to profile, but there are negative characteristics of a pit downdraft booth that often get overlooked. A characteristic that is most overlooked is that the filtration system lacks the longevity of other types of airflows. This is because only a small percentage of overspray does not collect in the filter area. Though pit downdraft booths do create a cleaner workspace, they reduce the time frame the filters can be in production. There is also an increased amount of labor and time associated with lifting the grating, removing and replacing filtration, and reinstalling the grating.”

Downdraft airflows also require subgrade work to be performed for the exhaust system as well, which can prove to be costly when considering construction and installation costs. When comparing the overall short and long-term costs of a spray booth, like the one required by DY Concrete Pumps, RTT proposed an alternate method of airflow design called a Side Downdraft. This design still allows for a softer downdraft airflow in the booth and the ability to have multiple painters, while also providing longer filter life, easier filter change-outs and above grade exhaust chambers.

“RTT provided us with the right solution of the side downdraft and saved us a lot of money by not having to put the pit in the ground”, says Chris Smith. Chris was not the only employee at DY Concrete Pumps that was impressed; he adds, “it has worked great. All of our painters are happy with the booth.”

Deciding what booth design is best for your product can be a challenging task, but when you partner with the experienced and knowledgeable team at RTT Engineered Solutions you can rest easy. Let RTT deliver the best product to fit the exact needs of your project and see for yourself!