A Quick Guide to Air Make-Up Units I RTT Engineered Solutions

At RTT Engineered Solutions, we provide Air Make-Up Units (AMU’s), as required by the NFPA, to replace air exhausted by the spray booth.

An indoor spray booth creates a negative balance in the air and can cause doors to be slammed shut or make them difficult to open, as well as exhaust both hot and cool air out of the building. The use of an air make-up unit prevents these issues.

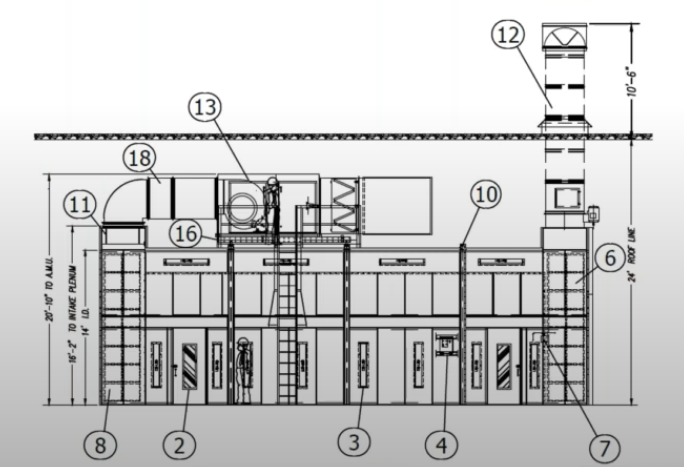

- Horizontal or vertical (on top or alongside booth)

- Located inside or outside of building

- “Demand” unit, multi speed / multi booth-building dumps

- Dedicated unit “pressurized booth”- ducted directly to the booth

- Recirculating

- Temperature and humidity control

- Horizontal or vertical (on top or alongside booth)

- Located inside or outside of building

- “Demand” unit, multi speed / multi booth-building dumps

- Dedicated unit “pressurized booth”- ducted directly to the booth

- Recirculating

- Temperature and humidity control

Dedicated Unit

The standard CT Series AMU replaces 100% of the exhausted air by the booth enclosure or building with fresh, filtered, tempered outside air. Features of the CT series include:

- ETL Listed to ANSI Z83.25 – CSA3.19

- G90 Galvanized Finish

- Automatic Booth Pressure Control allows the customer control to balance the booth and keep positive pressure within the booth

- Motorized Auto Gas Control

- Low Sound Level Forward Curve Fan

- All Digital Microprocessor, PID, Dual Set Point Temp Controller

- Four Programmable Recipes

What are some of the benefits customers see from the CT Series AMU?

- Lower noise level (dBA): It has larger duct work which is important when it is inside.

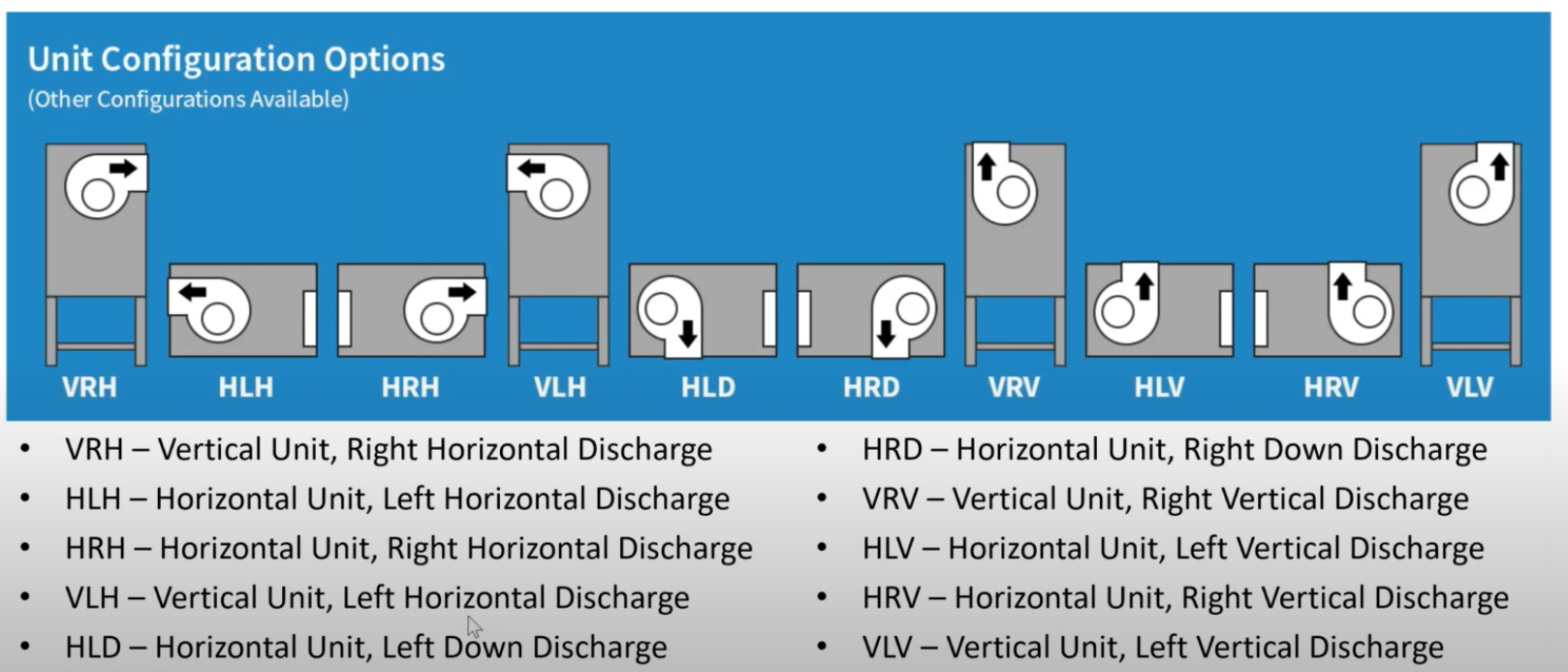

- Extensive layout configurations: These systems can be vertical, on the roof, outside and more.

- Innovative control package

- Energy savings

- Third party listings

- Highly customizable

- Low field wiring cost

- Eligible for our 5-year warranty: When the RTT RP W-Series Arrestors are used in the spray booth, the warranty includes the AMU’s, the booth and the E-Lights.

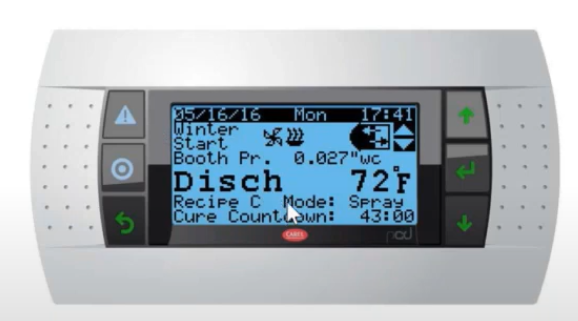

CT SERIES AMU: Controls

The control panel for this air make-up unit comes with a digital magnehelic gauge. The larger panel is standard but can be customized for the customer’s needs. There are also multiple user-adjustable recipes including:

- Spray Temperature

- Flash Time

- Flash Temperature

- Cure 1 Time

- Cure 1 Temperature

- Cure 2 Time

- Cure 2 Temperature

- Cool Time

- Cool Temperature

These units are very user-friendly.

Digital Magnehelic Gauge

Standard Control Panel

AMU MODELS

- Heat, Cure

The heat only model has a 90 degree temperature rise. It can also be adjusted down to lower temperatures when required. This model allows customers to heat with low speed cure as well, reducing CFM by half.

During the cure mode the temperature can rise to 160 degrees and customers can dry parts faster, increasing overall production. In a curing operation, the AMU is ducted directly to the booth and supplies air to that booth only.

The optional Prep mode feature is location on the controls. Once the operator is done spraying, the sprayer can be hung on gun hooks located inside the booth, which automatically communicates to the AMU that the booth is no longer in use and lowers the exhaust. This optional feature reduces operating costs for the customer.

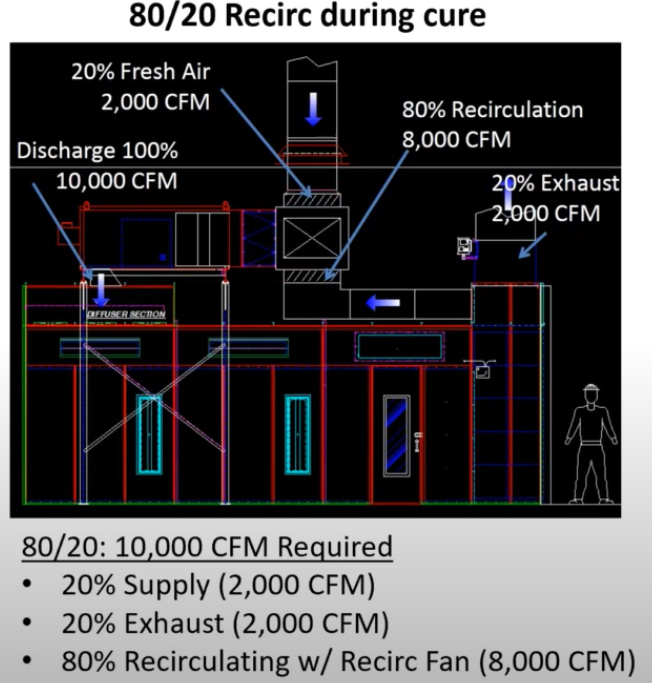

- Recirculation

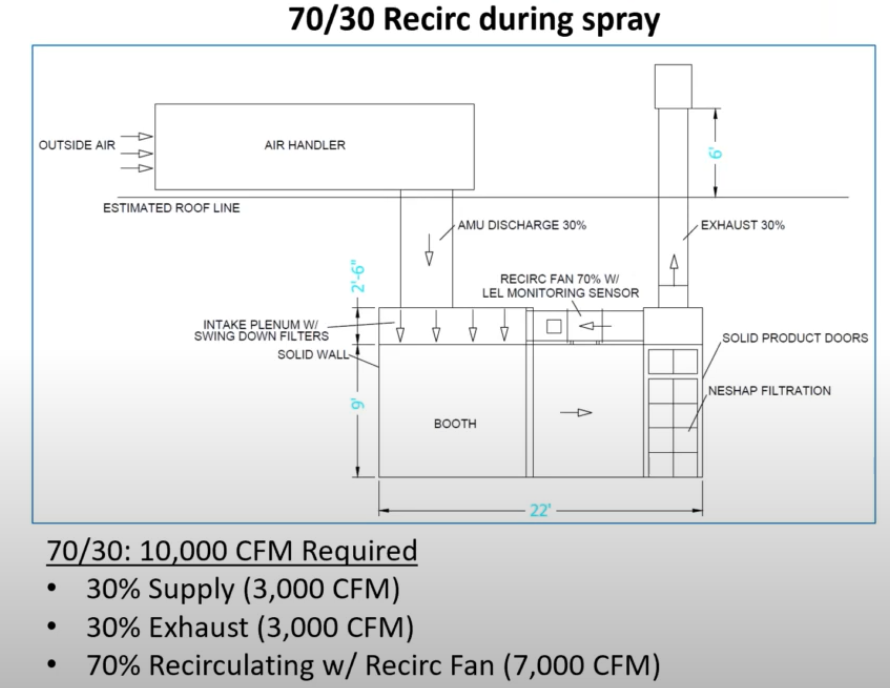

There are two common options for recirculation: 80/20 Recirculation during cure and 70/30 recirculation during spray. However, there are many custom designs that can be used to best serve the project at hand.

- Low profile: One of the options that we find fits the needs of many of our customers is the low-profile unit. Due to space constraints, often low profile is necessary. It fits well over the booth when there is structure above it. Instead of having a single fan that discharges, it will have 2 fans to shorten the unit. These units can get as low as 3-4 feet depending on size of the CFM.

- Installation & service: We can provide drawings and sizing, so the installation is easier for the customer. We offer an optional service platform and ladder that can be added to the booth, making it easier for the customer to get on top of the booth and maintain the AMU.

- Single phase: We can accommodate any power, but there are large motors in play which increases the amps and a customer might not have the ability to accommodate the amount of power it requires.

- Regulated gas inlet supply at 2psi, but custom gas pressure can be designed as required.

- AMU can be painted white, for an additional cost.

- RTT offers AMUs between 1,200-120,000 CFM.

Below is the information that is required in order to provide a quote for you.

- Voltage & phase

- 480V/3P, 230V/3P, 230V/1P

- Gas type

- Natural gas/propane

- Unit location

- Indoor/outdoor

- Unit orientation

- Horizontal/vertical

- Cure mode

- Airflow balancing:

- Auto manual, multi-unit input

- AMU mounting location

- Building roof, booth, floor

One of the most important things is the location of installation. If choosing the condensing unit, it is highly recommended to be outdoors.

The temperature and humidity range in the physical location are important, as the larger the range, the more expensive the operation becomes. If chilled water is available, the entering water temperature (EWT) is required. Also required is the leaving water temperature (LWT) and the Glycol type and percentage of the chilled water. If chilled water is not available, the DX Cooling system is an option and is generally less expensive than a chiller.

Ready for a quote

Have questions or need help in choosing the right RTT RP Air Make-Up Unit for your needs? Reach out and we will be happy to assist you.