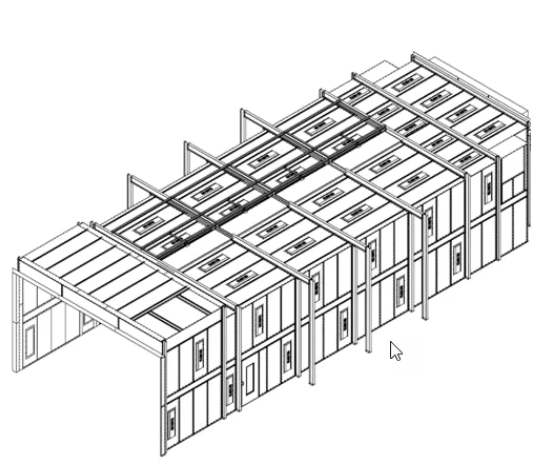

A custom paint booth using PNEUMATIC DOORS

Design challenge:

In order to install this paint booth, the customer, Supreme Manufacturing, Inc., had an overhead crane to maneuver the parts in/out of the booth. The use of a traditional open crane slot would require increasing the air flow, thus adding substantial costs to the project for upsizing the exhaust fans and AMU size; not to mention increasing the operating cost of the equipment.

RTT Solution:

A change was made to the standard paint booth design to incorporate pneumatic doors to close-off the crane slot after the parts were placed in the booth; therefore, we did not have to increase the airflow to account for the additional openings. As a result, we were able to save the customer substantial project and operating costs. Additionally, this paint booth was flashed-off to the building structure to allow access from outside of the building. Overall booth size: 25’ w x 15’h x 68’d.

Why is a paint booth required?

- A paint booth is needed to confine and evacuate atomized particulate and vapors within a restricted environment.

- Prevent overspray and volatiles from migrating and causing unsafe conditions or contamination outside of the designated spray area

- Provide a clean environment in which to paint and minimize contamination in the coated product

- Prevents a combustible combination of flammable vapors and air

- Required by OSHA and NFPA

A paint booth consists of:

- A work area/compartment where spraying takes place

- An exhaust chamber with filter media for collecting particulate

- An exhaust fan and motor ducted to the exterior of the building

- A paint booth can be open face, enclosed, or pressurized

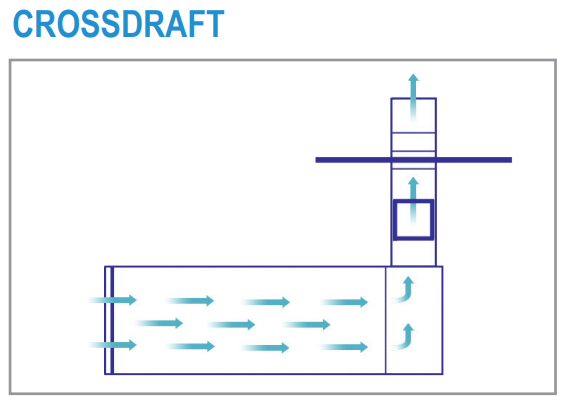

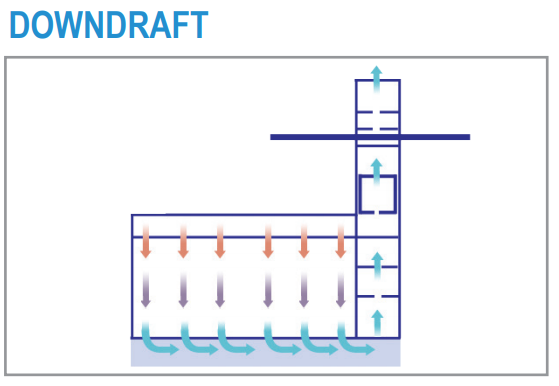

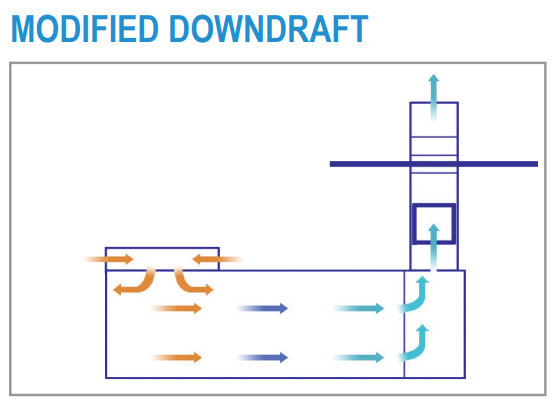

Paint booths are typically designed by the direction of the airflow.

Crossdraft booths intake air through filters in the product doors. The clean, filtered air is drawn through the booth and exhausted through a filter system at the opposite end.

Downdraft booths take in fresh air from the cleaner upper levels of the shop through a filtered booth ceiling. The filtered air is drawn down and away from the product into the filtered exhaust pit located in the floor.

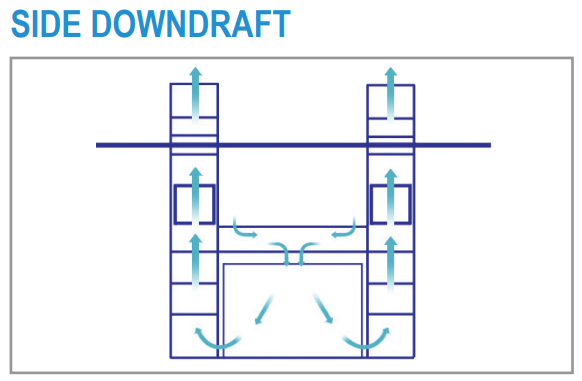

Side Downdraft booths intake air from the cleaner upper levels of the shop through a filtered booth ceiling. The filtered air is drawn down and away from the product through exhaust filters at the floor level, along both sides.

Modified Downdraft booths intake fresh air from the cleaner upper levels of the shop through a filter bank located in the booth ceiling, near the product doors. The filtered air is drawn down through the booth to an exhaust filter system at the opposite end.

Some quick highlights that we use to design our spray booths that are determined by OSHA and NFPA:

- Shall not be less than 100 linear feet per minute

- Electrostatic spraying may not be conducted at not less than 60 linear feet per minute

- The required airflow velocities range from 50-250 linear foot per minute (FPM) into the openings of a spray booth

- Dilute solvent vapor to at least 25 percent of the lower explosive limit

- The concentration of the vapors and mists in the exhaust stream of the ventilation system shall not exceed 25 percent of the lower flammable limit

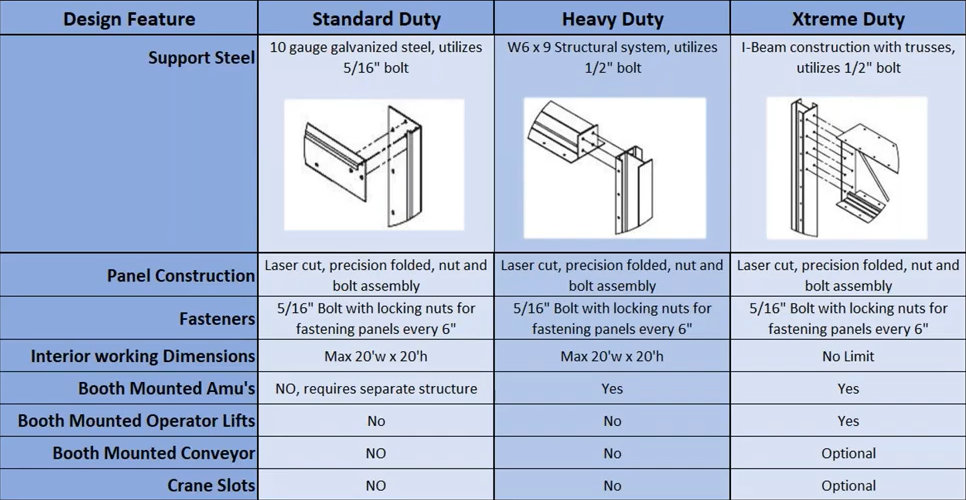

RTT Standard Designs:

We offer a wide range of standard booths that are pre-engineered, or “-S” booths. These booths have been drawn, detailed, the established customer packet has been set, and can typically be delivered within 10 days of ordering.

Ready for a quote

Have questions or need help in choosing the right custom RTT booth for your needs? Reach out and we will be happy to assist you.

For more information or assistance in specifying your RTT boothdesign, please contact your local RTT Distributor or contact us direct via email at sales@rttsolutions.com or via phone 888-452-6684.