TANGENT PROCESS

A COMPLETELY DIFFERENT APPROACH TO THE SPRAY APPLICATION PROCESS

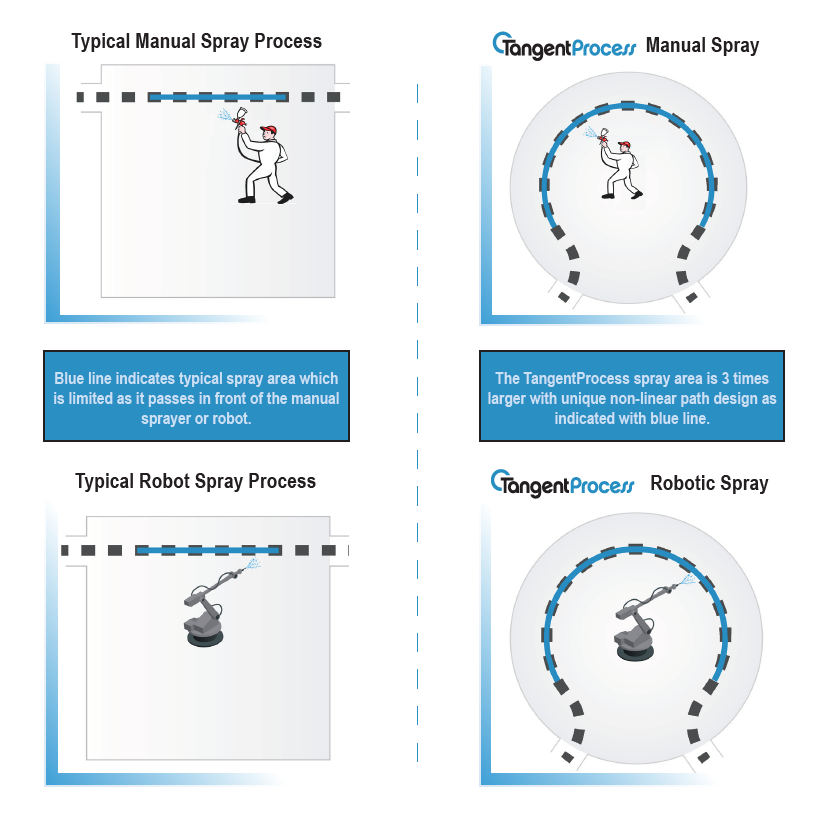

The patent pending TangentProcess by RTT moves away from traditional rectangular shaped booths and linear part travel to offer a completely different approach to the spray application process. The TangentProcess accommodates a non-linear conveyor path, which increases the available application time allowing the product being coated to be in the process area up to three times longer. In addition to more time, the process also maintains optimal applicator to product target distance allowing for increased transfer efficiency and improved quality.

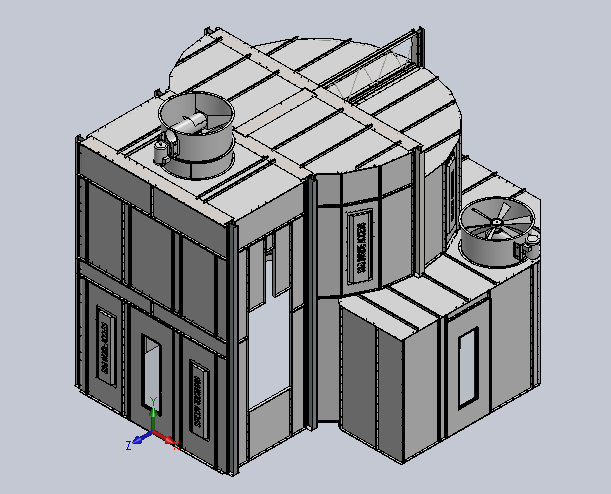

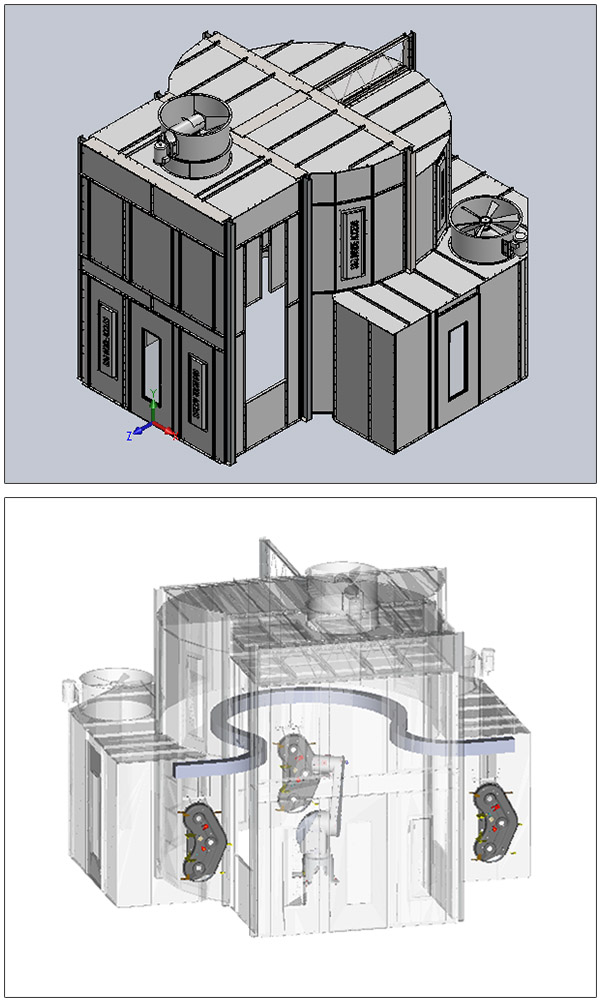

Once the optimal part path has been established, the TangentProcess spray enclosure is custom designed to complement the desired process and maximize capture efficiency. These optimizations can include multiple exhaust chambers which eliminates downtime for required filter change outs.

The TangentProcess can be used for Manual, Robotic, Liquid or Powder applications. When used for robotic powder applications, the booths design allows the robot to perform booth blow down operations for cleaning and color change. If two robots are installed, the robots may even be used to clean each other.

Features & Benefits

- Patent pending technology where the parts travel around a manual spray operator or robot that is applying the coating or material.

- Offers a 3 times longer spray time than typical linear conveyor systems.

- Changing exhaust filters can be achieved without stopping production reducing downtime in some applications.

- Capture of overspray is maximized by unique booth design.

- Booth design based on coating process requirements and can easily be adapted to customers process

- Dependent on cycle rate, all sides of a part can be sprayed by simply rotating or indexing the part while in the booth.

- Booths are designed to allow for robots to either be placed on the floor or hung from overhead. An additional robot can be installed in the booth on the same centerline as the existing robot.

- Compact, space saving design improves efficiency.